Product

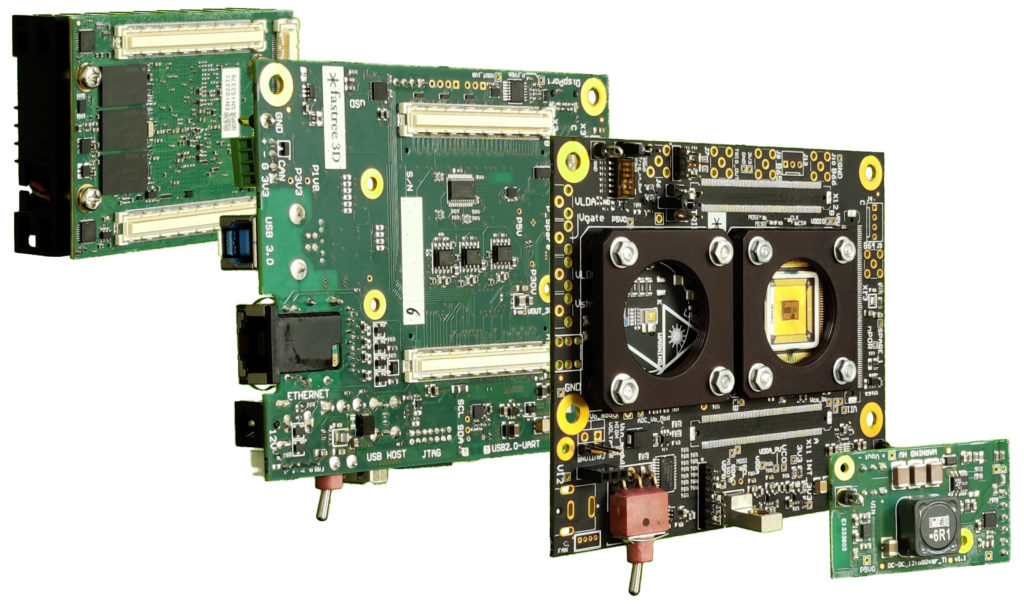

Falcon is Fastree3D’s Hardware Development Kit (HDK), designed to facilitate the commissioning, demonstration and development of Fastree3D’s LiDAR solutions. It supports a rich set of interfaces, enabling the integration of our LiDAR technology into a third-party system. It is intended to be used by partners who can tailor the system performance to their specific applications.

The HDK includes the illumination sources and drivers, a sensor chip fabricated in a standard CMOS process, and a System on a Chip (SoC) which provides computing and signal processing functionality. The ASIC (Application Specific Integrated Circuit) sensor chip consists of an array of single-photon sensitive detectors (SPADs), Time to Digital Converters (TDCs) and digital pre-processing circuitry.

Our HDK module generates a point cloud of the distance measured at each pixel, tagged with a quality of result (QoR) that provides an assessment of the reliability of the measurement. It also provides intensity information for each pixel. The HDK is designed to be plug-and-play. It can operate standalone, connecting directly to a screen and USB peripherals or be easily integrated into your system.

Contact us to find out more about the HDK

Advantages

Our vision system benefits you by:

ELIMINATING FALSE DETECTION. Reduce false negative and false positive detections. Our sensors provide direct reliability quantification of each distance measurement you performed.

MINIMIZE LATENCY. A high frame-rate is not enough. Analysis of raw-data from multiple frames requires pipeline processing, resulting in high latency which introduces a “blind time” of several hundreds of ms (up tens of meters at automotive driving speed). To minimize the detection-reaction time, our sensors implement edge processing, bringing the computation into the detector itself using a System-on-Chip (SoC) approach.

INTELLIGENCE. The camera has different operating modes (distance or intensity). Additional edge computing can be performed to improve sensor fusion.

AFFORDABLE TECHNOLOGY. The simplest design (flash, no scanning), in standard CMOS technology to leverage the economy of scale of consumer electronics.

How does it work?

Fastree3D imagers are flash LiDARs (Light Detection And Ranging) based on direct time of flight technology. The distance to objects is determined by measuring the time taken for a light pulse to travel from the imager to the object and back again. The on-board illumination module generates light pulses that illuminate the entire scene at once, like in conventional photography, without the need for any scanning/rotational optics. Our proprietary, CMOS-based sensor detects the reflected pulses and determines their time of arrival, thereby allowing the Digital Data Processor, embedded in the System on Chip (SoC), to measure the Time-of-Flight (ToF) and consequently the distance. It’s that simple!

Low latencies, high reliability and robustness define our imagers. These attributes are the consequences of our technological approaches. Our measurement technique (based on Time-Correlated Single-Photon Counting) enables the evaluation of a per pixel quality measurement, in real time. The single-photon sensitive detectors (SPADs) mark the digital nature of the sensor. In other words, simple, digital, fast.

The key features

FAST ACQUISITION SPEED. To provide awareness we need to have a representative data sample of the situation.

RELIABILITY ASSESSMENT. Each distance measurement performed by each pixel is provided with a quality of result. It is essential to trust in the data, they are driving the decision.

FLEXIBLE OUTPUT. The camera offers multiple operating modes (distance, intensity). Choose on the fly the one that better helps to complete a task. These features derive from the technology choices and hardware implementations we chose.

Improvement from the past

Conventional vision systems were developed around human needs (e.g. color sensitivity, resolution) and not those of automation. Even high-end sensors provide at most a distance measurement, and lack critical information required to avoid collisions. Machine vision can be improved with a high-confidence measurement of speed, direction and distance at low latency.

THE SOLUTION : Our sensors meet the three requirements for motion detection:

SPATIAL AWARENESS: rapidly monitors distances and motion around the camera.

TRUSTED INFORMATION: reliable measurements, even in adverse situations and with a confidence level assessment.

INTELLIGENCE: adaptive system capable of selecting the best operating mode for a given condition.

Applications

Car

Our technology enables safer driving and autonomous navigation by continuously monitoring the surrounding space, avoiding collisions by measuring the distance to objects with high confidence.

AGV Forklift

Improve safety and productivity in your warehouses with our camera technology to provide forklifts and AGVs with 3D spatial awareness.

Robot

Get the most out of human-robot collaboration guaranteeing safe interaction: enable small customized batch manufacturing at the price of mass production.

Services

Workshop

Are you new to the 3D vision field and unsure which solution would work better for you? You already know about the possible technologies you would like to explore product concepts with us? We offer educational and co- creation workshops to:

- provide you with the knowledge you need to determine whether our or another 3D vision solution is right for you.

- Design solutions around your application tailoring our technology at its best.

![]()

FEASIBILITY STUDIES

You have in mind several problems but you do not know which to tackle first? You are interested to know which one our technology would be better solving? We offer joint feasibility studies to investigate your application and your challenges. We developed a software to simulate the performances of our technology in your specific conditions. Optimize your resource allocation focusing on the right problem straight away.

Hardware Development Kit

Do you want to design new automation possibilities, guide the mobility revolution, or transform safety on your factory floor? Do you want to lead these transformations with a new generation of products and solutions which will make you stand out from the competition? The Hardware Development Kit (HDK) is the platform to explore the new possibilities of Fastree3D’s flash LiDAR technology. The HDK will be available to a limited number of partners. Contact us if you are interested in application development.